Dosage of concrete mixes

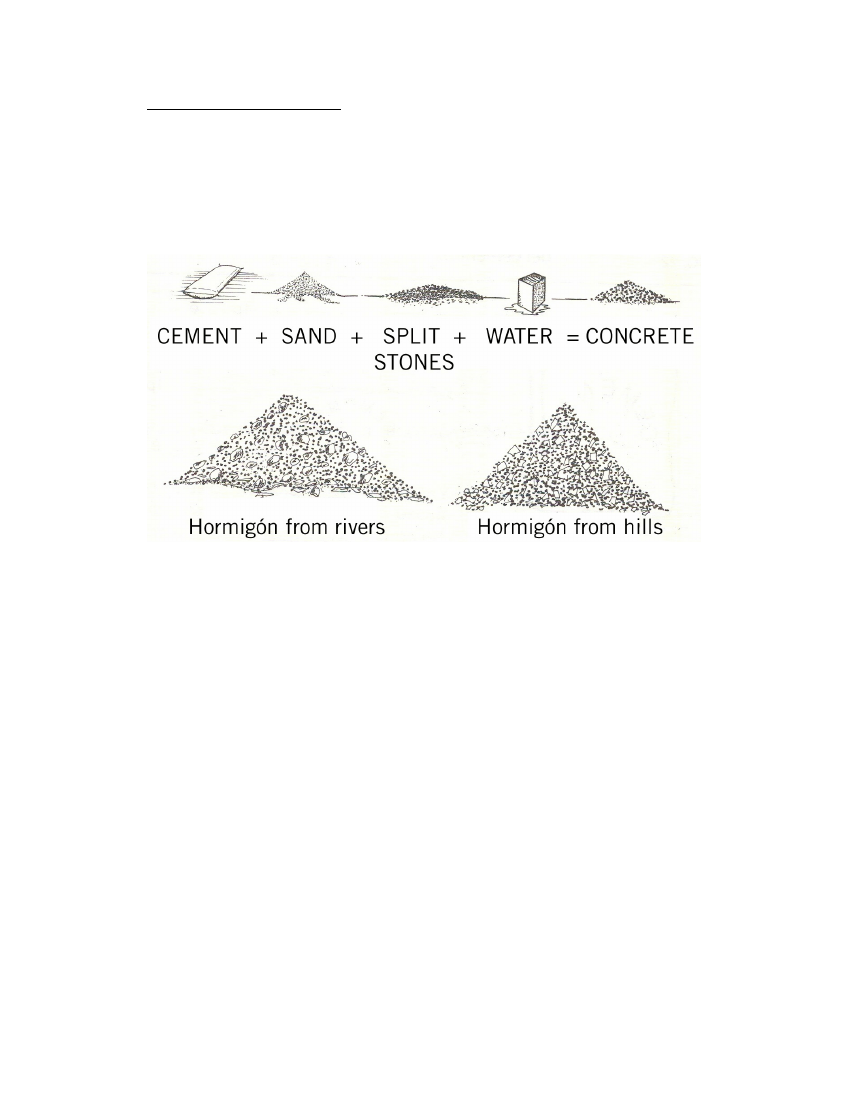

Concrete is a mixture of cement, aggregates and water.

Examples of aggregates are ‘hormigón’, sand, stones, and slag from furnaces.

‘Hormigón’ is a mixture of stones and natural sand found in quarries. Stones

from river quarries are round and stones from hill quarries are angular. The

sand may be thick or fine and both kinds of stones are of variable sizes.

HORMIGÓN = SAND + STONE

Fig. 21

To obtain the right concrete mix – and thus the desired type and resilience of

concrete -, it is important to blend the correct proportions of aggregates

(cement, sand and water).

There are two methods of doing this: 1) by weight, and 2) by volume, of the

concrete components. In both cases the aggregates should be free of organic

matter and have the recommended or specified hardness and size. The water

must be clean, fresh and free of organic matter, salts, acids, etc. The cement

must be fresh and in good condition.

The most advisable way to prepare the mix is by weight, as it is economical and

the results are good. However, your dosage plant must have large-capacity

scales, mixers, transport equipment, cement silos and aggregates classified by

diameters.

Preparing the mix by volume is a reasonable alternative to weighing, whereby

the weight of each component is converted to volume based on volumetric

weights of the aggregates and the cement.

22